Surface-Toolpath Twins of Shell Components in 3D Concrete Printing

Authors

Project Date

2025

Awards

Related Publications

Acknoledgements

The authors gratefully acknowledge the support provided by the Advanced Research Projects Agency Energy (ARPA-E) Grant of the U.S. Department of Energy (DE-AR0001631) and the National Science Foundation Future Eco Manufacturing Research Grant (NSF, FMRG-CMMI2037097) awarded to Masoud Akbarzadeh.

The authors also thank Mostafa Akbari for providing digital models of shellular structures as test examples, Yao Lu for help in Grasshopper plug-in development, Teng Teng for the fabrication platform, and Maximilian E. Ororbia and Amir Motavaselian for providing and fabricating the test geometry in construction scale.

Description

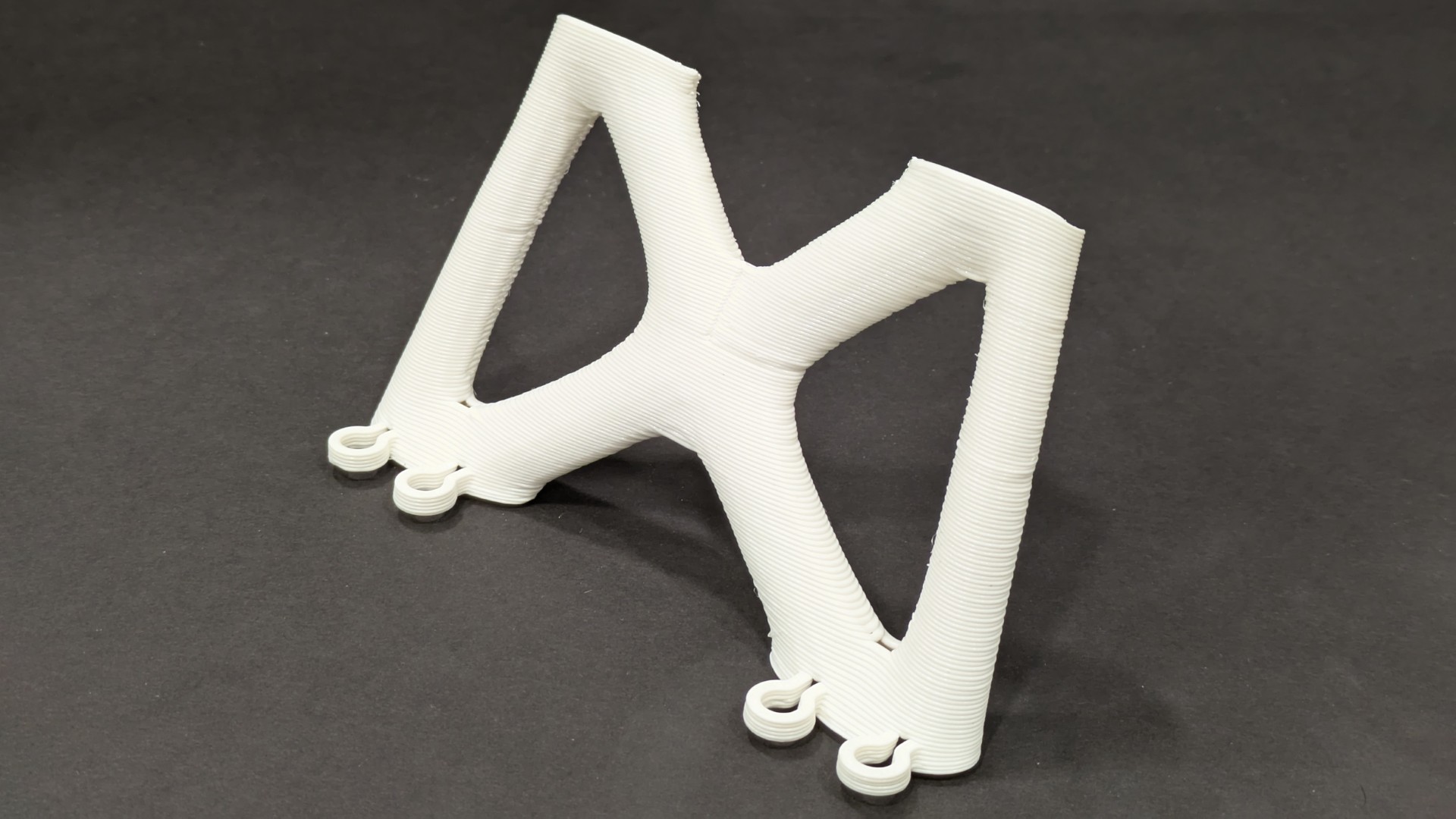

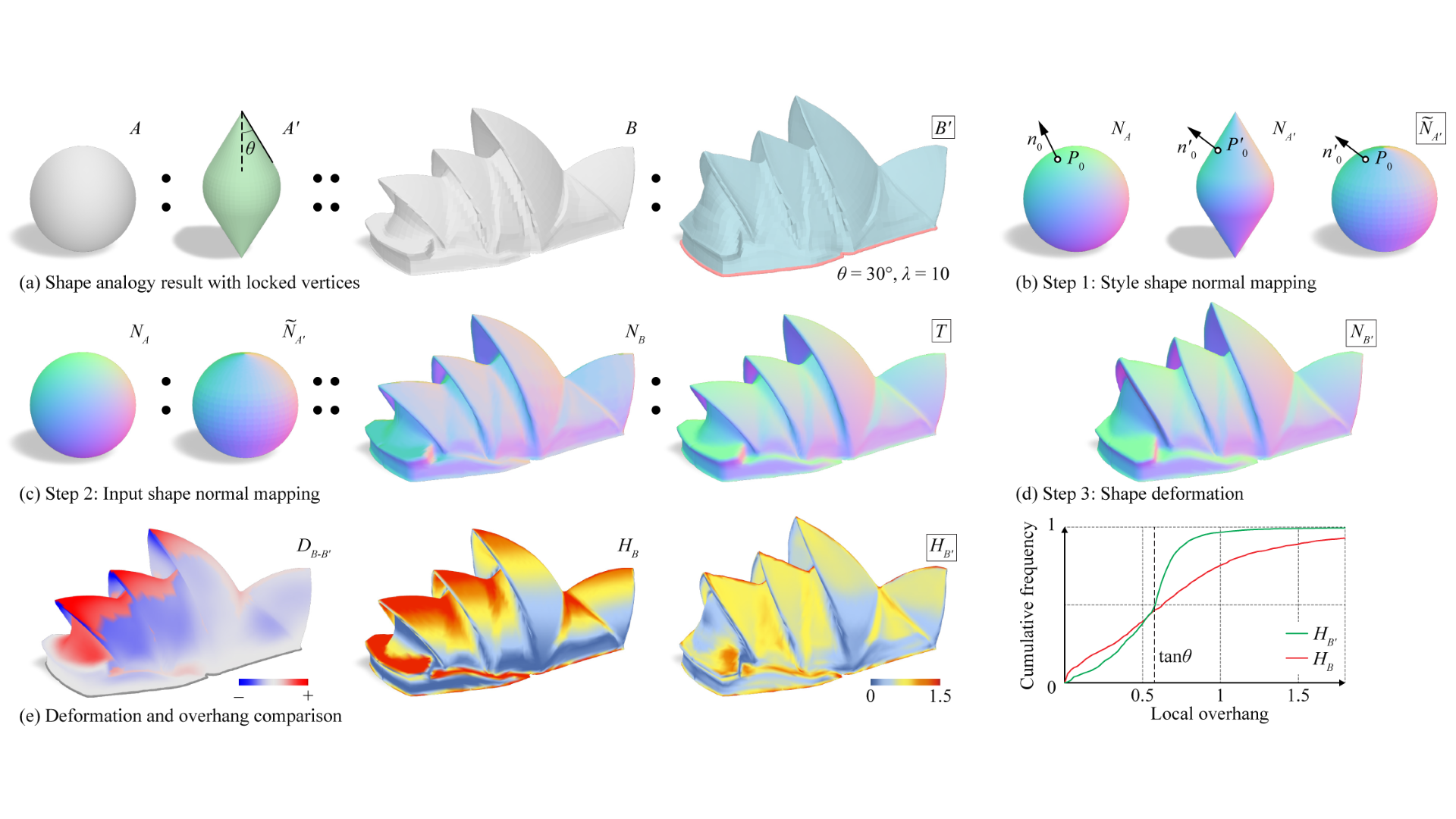

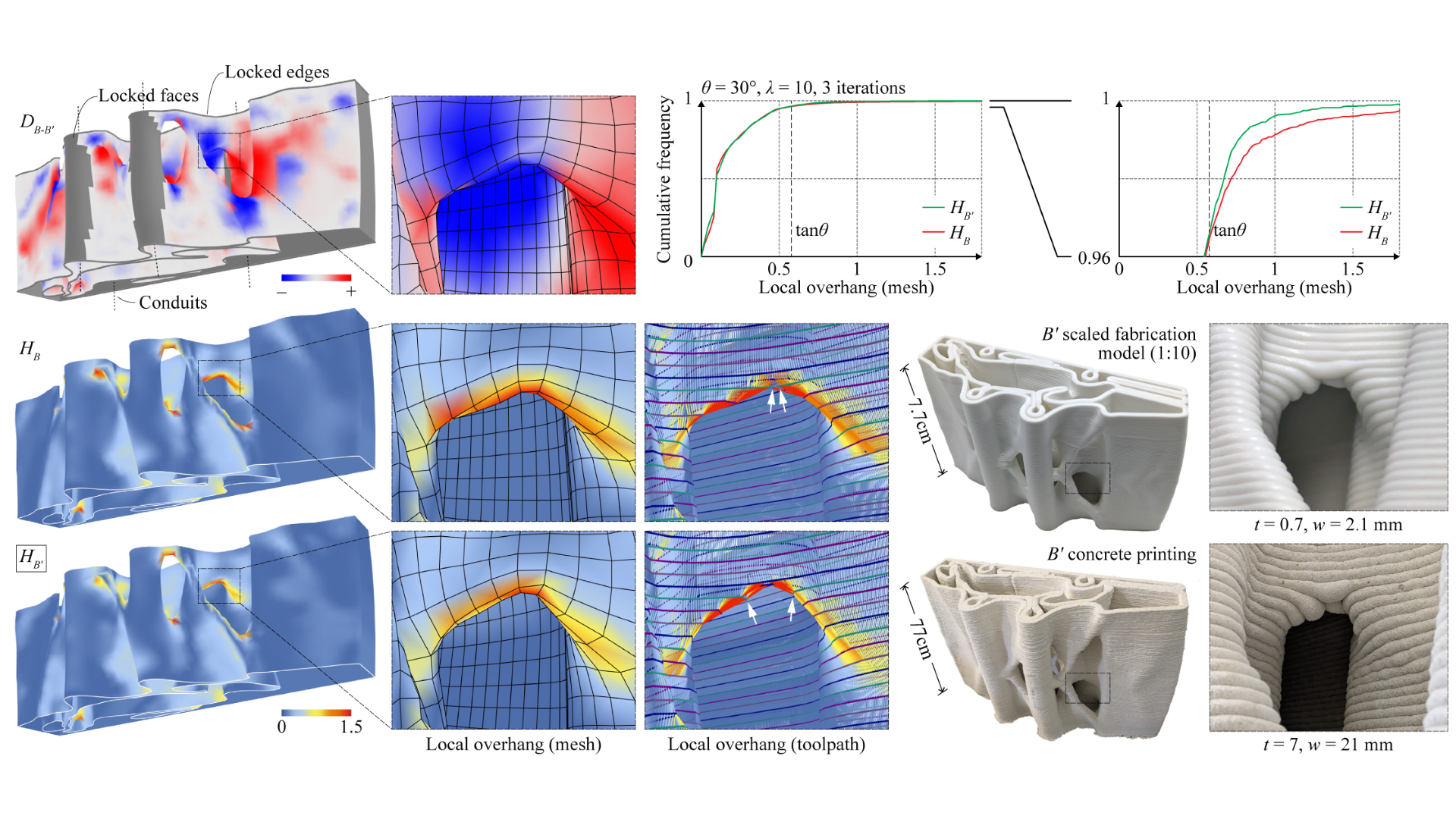

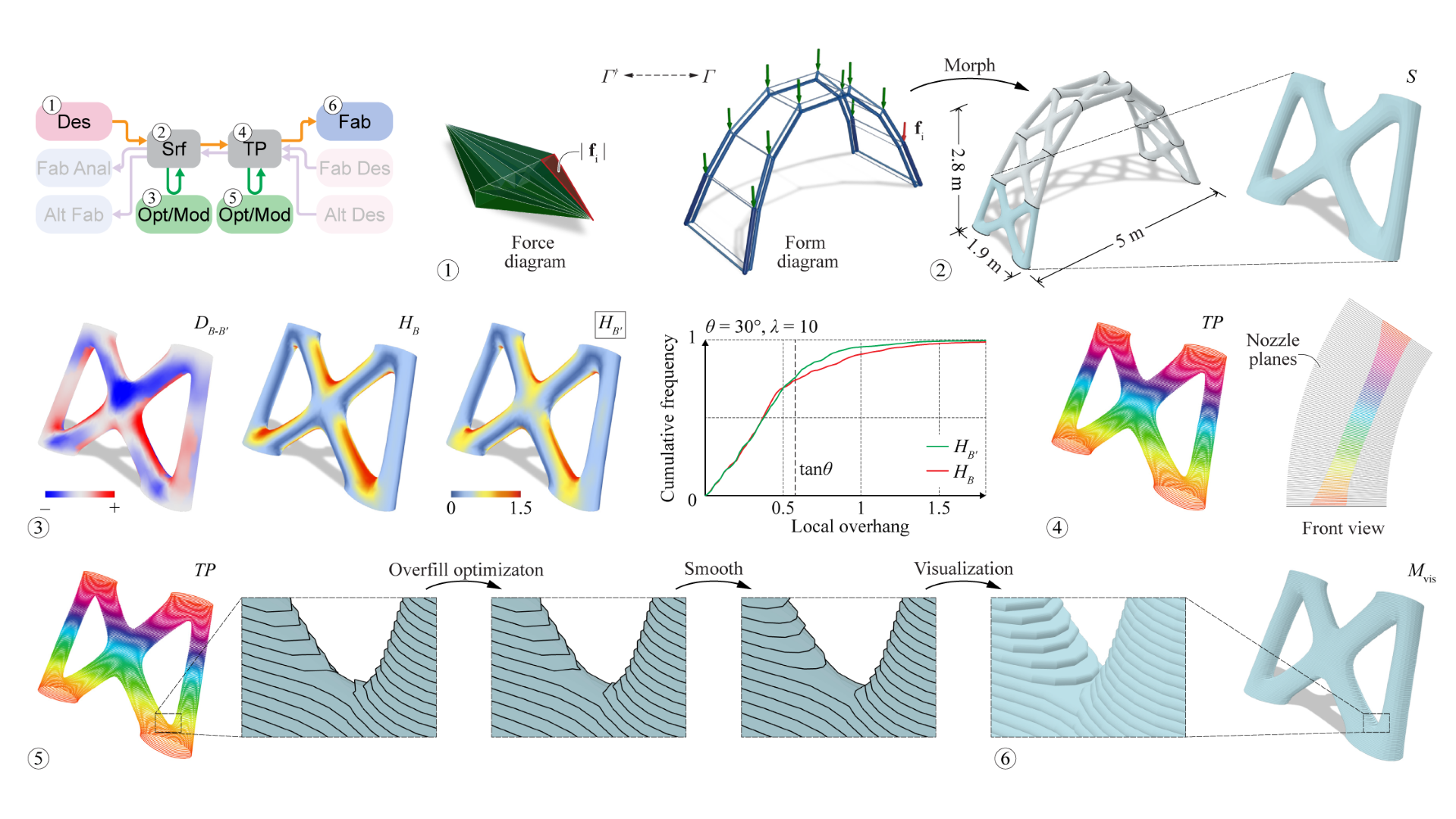

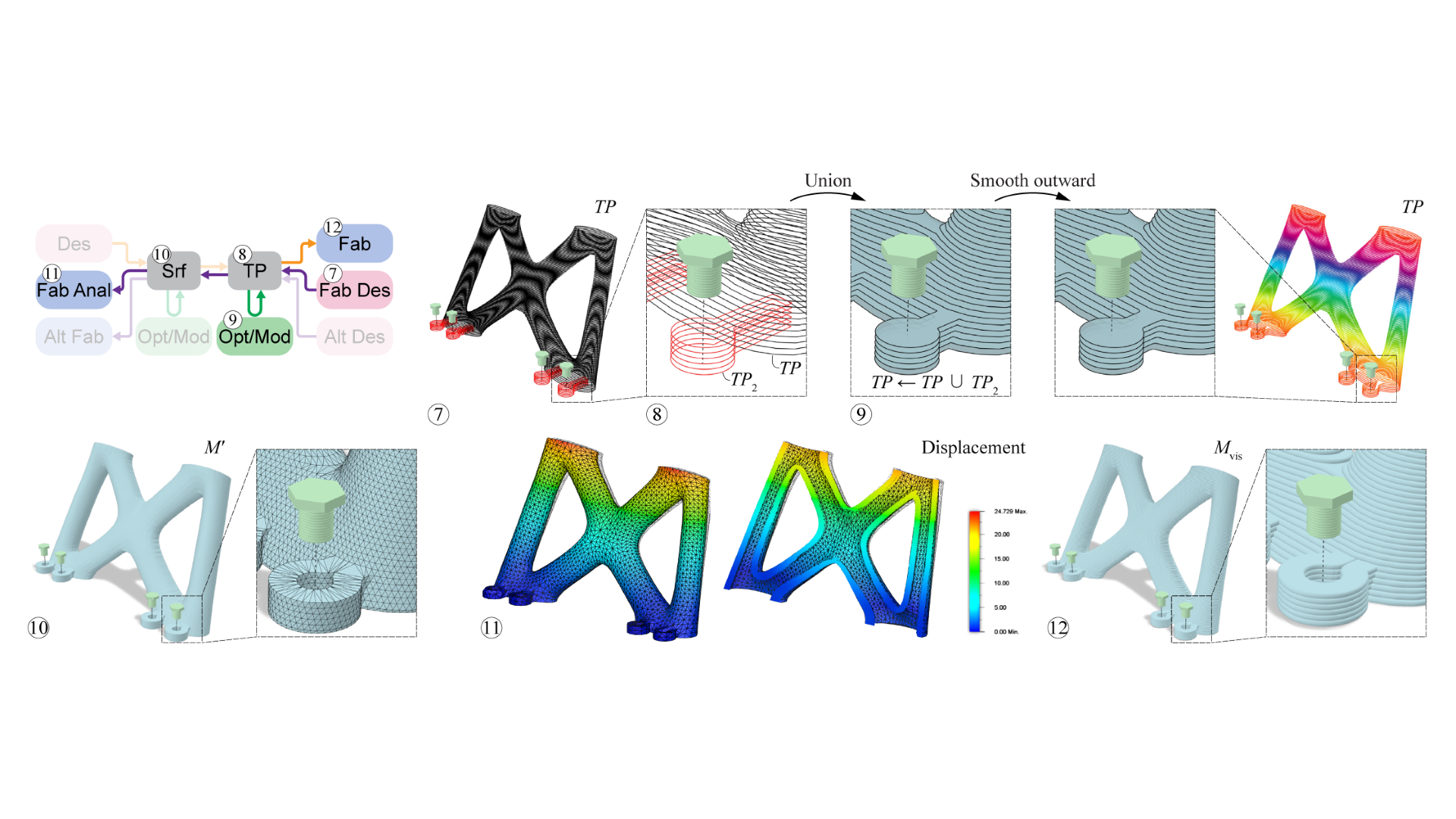

This study directly links the abstract geometry of structural form-finding to the fabrication-aware design of discrete shells and spatial structures for 3D concrete printing through a bidirectional approach that creates surface-toolpath twins for the components, optimizing their buildability and surface quality. The design-to-production process of efficient structural systems for 3D printing is often a top-down unidirectional process involving form-finding, segmentation, and slicing, where results face printability challenges due to incompatibility between the initial geometry and the printing system, as well as material constraints. We introduce surface-toolpath twins that can be interconverted and synchronized through efficient slicing and surface reconstruction algorithms, allowing for the combination of optimizations and modifications on either part of the twin in flexible orders. We provide two core methods for fabrication rationalization: (1) global buildability optimization on the surface mesh by normal-driven shape stylization and (2) local surface quality optimization on toolpath curves through intra-layer iterative adjustments. The result is a bidirectional design-to-production process where one can plug and play different form-finding results, assess and optimize their fabrication schemes in the conventional way, or leverage knowledge in fabrication design, model toolpath curves as sections, reconstruct surfaces, and merge them into form-finding and segmentation in an inverse way. The proposed framework enables the integration of form-finding expertise with fabrication-oriented design, allowing the realization of spatial shell structures with complex topologies or extreme geometrical features through 3D concrete printing.